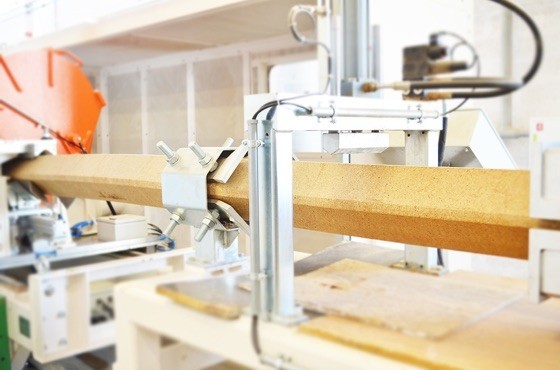

Until now, pallet blocks were made mainly of solid wood. However, due to the fact that wood is a relatively limited resource, Baltic Block has gone one step further and offers producers of pallets a product made of leftovers from the wood industry that might otherwise not be used. This attests to the company’s prudent use of a natural resource, as well as its skill in using this resource to manufacture a high-quality product. With the help of modern technology, leftover wood is mixed with glue and, using a special extrusion method patented in Italy, three- metre-long sections are treated with steam, the glue hardens, and then the product is at the right consistency to be sawn into sections of the required length. Baltic Block began developing its business plan before the recent economic crisis, when it still owned a pallet manufacturing plant. But it was difficult for the company to obtain largedimension EPAL pallet blocks for a reasonable price, so it began looking for other solutions. And so, step by step, the ambitious plan has come to fruition. Having overcome the economic and financial crisis, the business partners were satisfied that their business plan was correct. A second key to success is, perhaps, stubbornness – that they did not give up at the first, second or even third instance of difficulties. And, according to Baltic Block, its third key to success is undoubtedly its team of employees, which has grown by leaps and bounds since the beginnings of the company, when there were only two employees.

Edgars Šķēle, co-owner

Export Markets

Austria, Belgium, China, Czech Republic , Denmark, Estonia, Faroe Islands, Finland, Germany, Greece, Hungary, Israel, Italy, Lithuania, Netherlands, Poland, Qatar, Slovakia, Sweden, Turkey, United Arab Emirates

Andis Šķēle

andis.skele@gmail.com